Fabrication Services

3D Equipment Modeling

We create detailed three dimensional models in Solidworks for all of our custom equipment. This enables clients to review, edit and approve the design and ensures the fabricators construct the equipment with a high degree of accuracy.

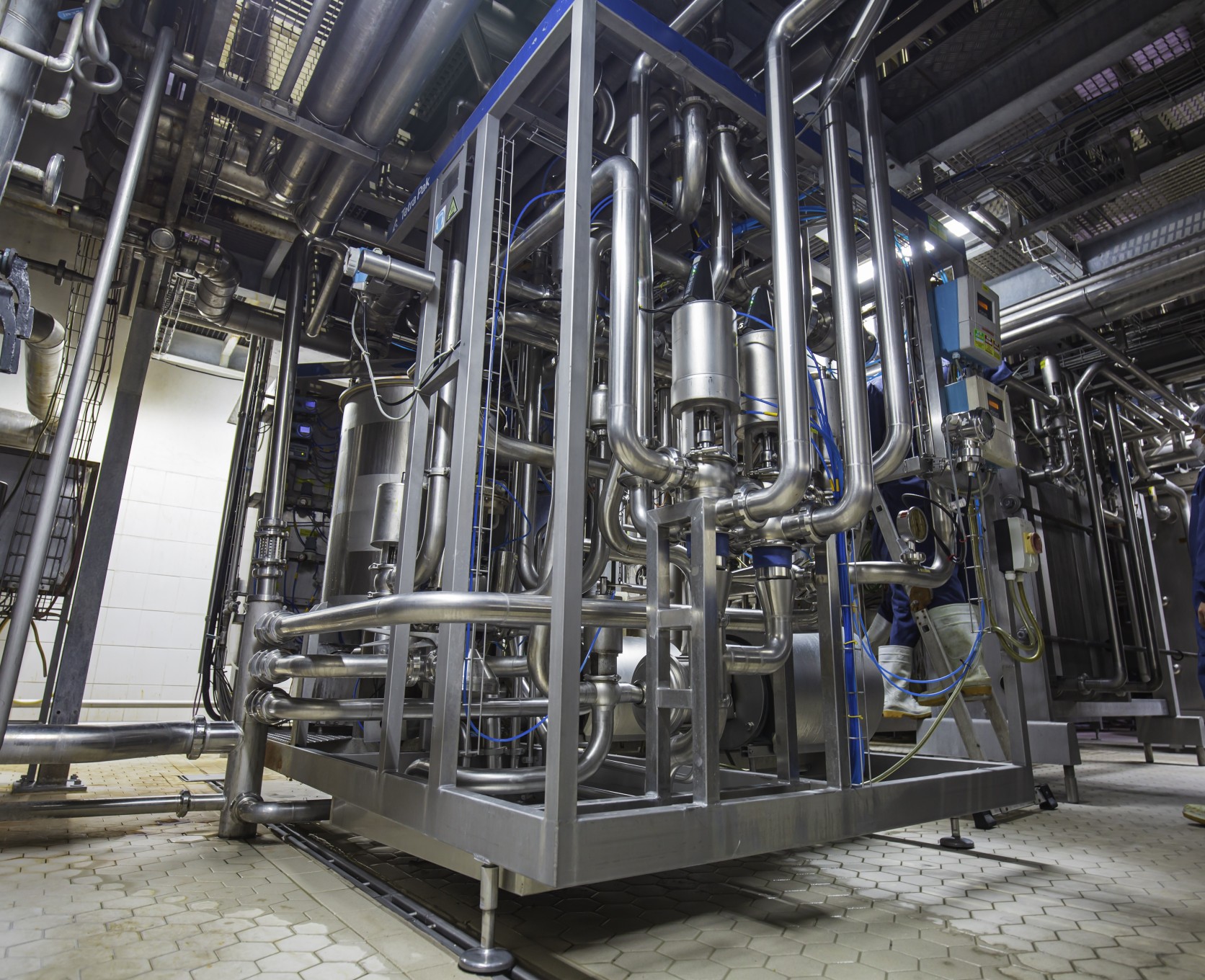

Industry Expertise

Our engineers, welders and fitters work exclusively in the sanitary process industry, with decades of experience with the parts and materials of construction required in these plants.

Custom Equipment

We can design and fabricate a wide variety of custom equipment including: Valve clusters, pump carts, flow panels, CIP systems, Mixing & blend systems, tote stands, hot water sets, platforms & mezzanines, and hold tubes.

ASME Certified Welders

Our welders are ASME certified in both manual TIG welding and auto-welding. They can weld structural members, schedule piping, sanitary tubing and sheet metal in a variety of high purity materials including 304L SS, 316L SS and AL6XN.

Orbital Welding

We have great hand welders, but they are also experienced operating modern orbital auto-welding machines if a project requires it.

Acceptance Testing

We can help prepare and execute factory acceptance testing [FAT] and site acceptance testing [SAT] protocols for our projects.